Turbine Logging System

BA833 Turbine Overspeed Trip Logging System

Steam turbines can become unsafe if the overspeed trip becomes faulty. Regular checking of this trip must be carried out. This can be hazardous using a simple handheld tachometer.

This Turbine Overspeed Trip Logging system has been developed to check the operation of steam turbines. The speed of the turbine is monitored using an optical sensor, the logging system can be mounted up to 30 meters from the sensor. This allows the overspeed trip speed to be monitored and recorded with greater safety that using a simple tachometer. The results are logged together with time and date stamp so that it can be demonstrated that the test has been carried out.

The speed is logged for 5 minutes and can be downloaded to a PC. The results are stored in an Access database and a graph showing speed against time can be viewed onscreen and then printed out. 32 sets of results can be saved in the instrument for later downloading.

For each set of readings the instrument will display, the maximum speed and the maximum rate of change. These can be compared against the specification for a particular turbine and an alarm raised if the values are exceeded. There is also the option at the start of a test of specifying if the test is an overspeed trip or a letby. It will also record if the test turbine is coupled or uncoupled. Tests can also be carried out to log the rate of speed reduction during spindown. This provides a useful check on the operation of the turbine.

The system consists of 4 parts.

1. A remote optical sensor. This is mounted at a distance of approximately 6 inches from the moving shaft. The Sensor has standard cable length of 10 Meters (longer lengths are available to order.)

2. The Turbine Logging instrument. The sensor is plugged into this instrument which then displays and stores operating speed. This has a backlit LCD display together with a membrane keyboard for selecting logging function. It is fitted with rechargable batteries. This unit has environmental protection to IP65 and has a wriststrap.

3. The Turbine Logging Instrument interface pod. The instrument is placed in the pod after use to recharge the batteries and transfer the data to a PC via serial connector.

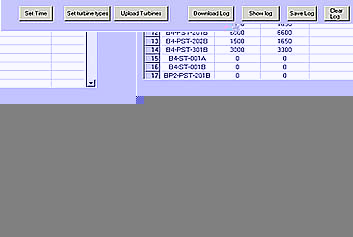

4. Turbine Logging Windows software which will run on a wide range of systems including Win95/98/ME/2000/XP. All the turbines on a site can be entered in the database, this will include part number, trip speed and run speed. This information can then be transferred to the logger before testing.

When the set of Turbine Logging tests are completed the results are transferred to the PC. The results are then stored in an Acess database containing time and date of test, maximum speed and maximum ramp rate.

A graph can then be displayed of the test, this can be printed if a hardcopy is required.

![]() The system was pioneered in association with ESSO (Exxon Mobil) Fawley Refinery. The product is now accepted as best practise for the corporation worldwide.

The system was pioneered in association with ESSO (Exxon Mobil) Fawley Refinery. The product is now accepted as best practise for the corporation worldwide.

Click for a Free Quotation

Part No |

Description |

B833 |

Turbine Logging System (including sensor) |

B833-SEN |

Logging System Sensor |